RevitMEP Implementation - You thought it was about taking on new software, and are finding there's a lot more going on.

RevitMEP is solidly the platform for collaboration, design and construction for the near and foreseeable future. For MEP Contractors, Revit is not a clean, contractor specific solution...

How will you fit all the pieces together, and still progress?

As co-founder of TSI, the company that brought CAD-Duct / CAD-Mech to the market (known now as CADmep), Greg Davis has incomparable knowledge among consultants in the setup, use and potential of itm data content, as well as an understanding of where families fit in. There are several options out there, for data, for add-on products, for tie-in to field machinery like Robotic Total Stations. Now, years later as a consultant and as founder of Dolphin, Greg brings his experience and skills to contractors to fill in significant gaps. Contractors find consulting from Dolphin critical to having a clear understanding of their options, and a real plan to best implement Revit.

For all of the potential of the Autodesk acquisition of the Fabrication products from MAP software, progress always relied on partners to fill the implementation gap. I aim to fill that gap for contractors. - Greg Davis

One the surface, learning how to use Revit and training your team is a big challenge. Learn these additional mission critical hurdles you need to overcome to...

empower transformation to Lean Manufacturing.

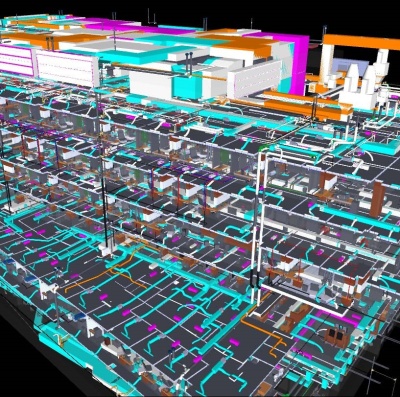

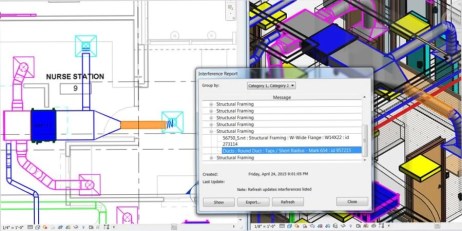

Make RevitMEP a part of a comprehensive BIM to Fabrication to Installation closed loop offering a true continuous improvement (Lean Manufacturing) process.

Review these 6 critical areas we can help you address to plan and implement the right tools:

- Who creates spools now, and who would you have select and create spools in the future?

- What consistency of process do you need to put in place to automate spooling selection and manufacture more consistently?

- What items do you not draw? How do you account for and order these items? How do you compare these to estimates?

- At what point in your process are you committing to orders from suppliers? Are you leveraging the optimal purchasing scenarios?

- What annotation (CAD Model) and reporting requirements do you have for your customers? What plan can you put in place to cut your costs, while meeting customer demands?

- What are your required data and model outputs to facilitate fabrication, layout and purchasing? Have you mapped these needs before seeking software solutions, or have you let the process be driven by others?